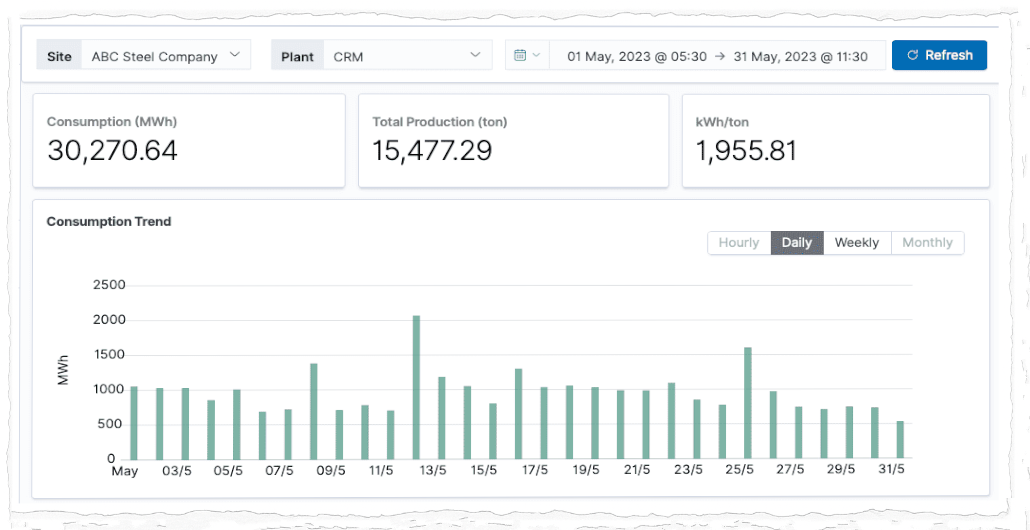

Track consumption patterns

Monitor real-time energy consumption by overall Plant and drill down to function and meter. View historical trends of energy, power, current and voltage.

- Shift-wise consumption

- Track by hour, day, week and month

Track specific energy

Monitor consumption vis-a-vis production. The app auto computes specific energy (kWh/ton) by merging energy data with daily production output.

- Is consumption aligned with production?

- Requires production data (tonnage/qty)

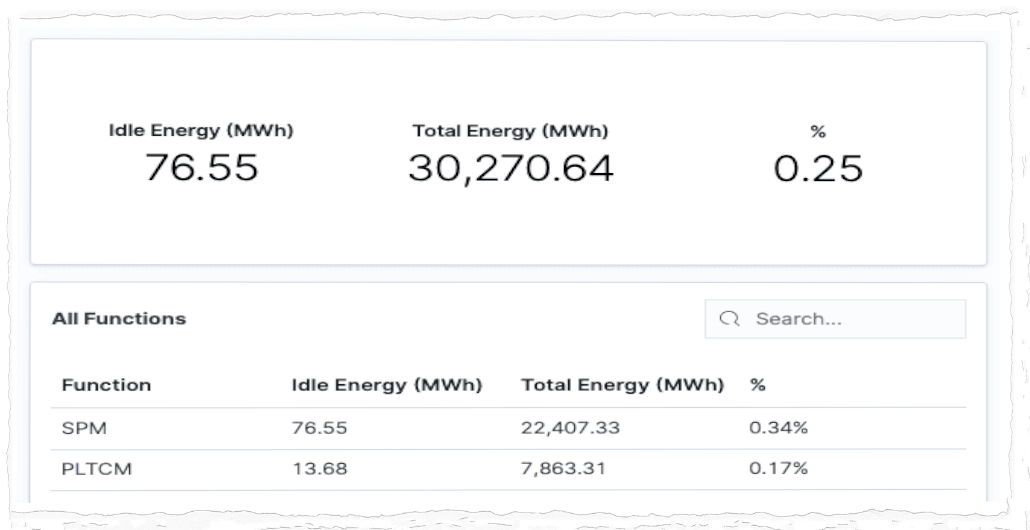

Track idle energy (wastage)

Quantify energy wastage due to equipment idling between production stops. A built-in algorithm with configurable options for detecting idleness.

- Enhances stability and life of equipments

- Reduces CO₂ emissions

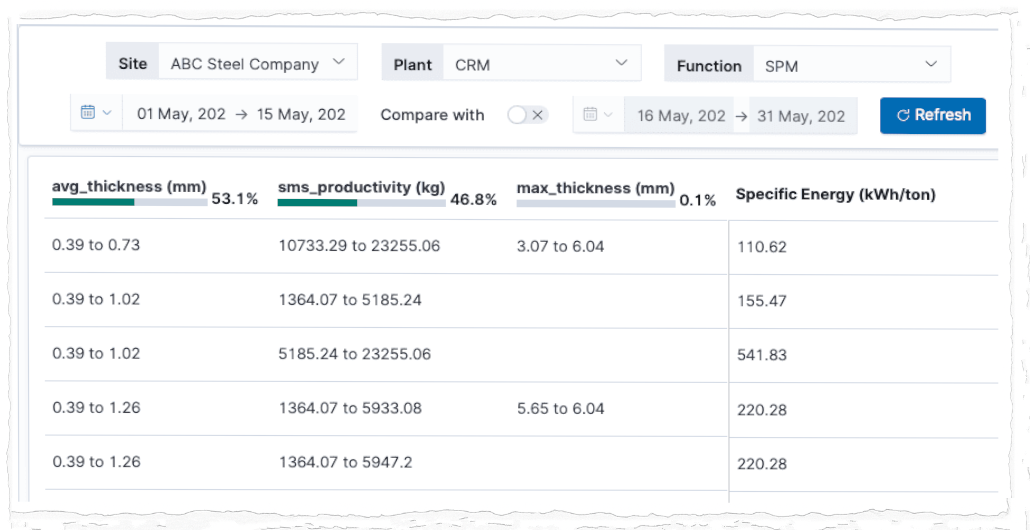

Product variation & benchmarking

Slice and dice specific energy for various product specs. The app auto computes product-level benchmarks based on past consumption patterns.

- Automatically models consumption pattern

- Better planning to match demand

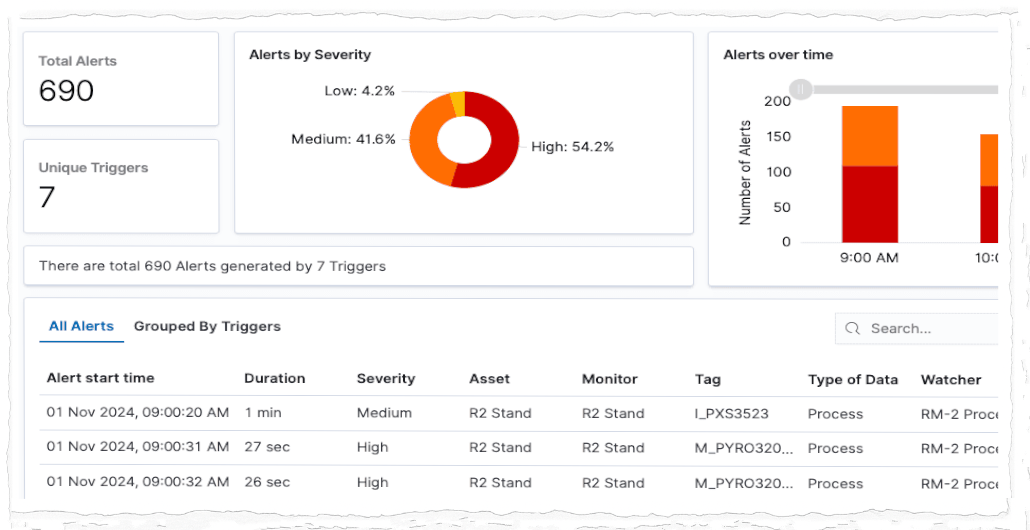

Alerts & Reports

Configure alerts on various power parameters. Generate reports, export raw data, or use APIs to integrate energy data with other applications.

- Create custom reports and alerts

- Threshold-based or aggregation alerts

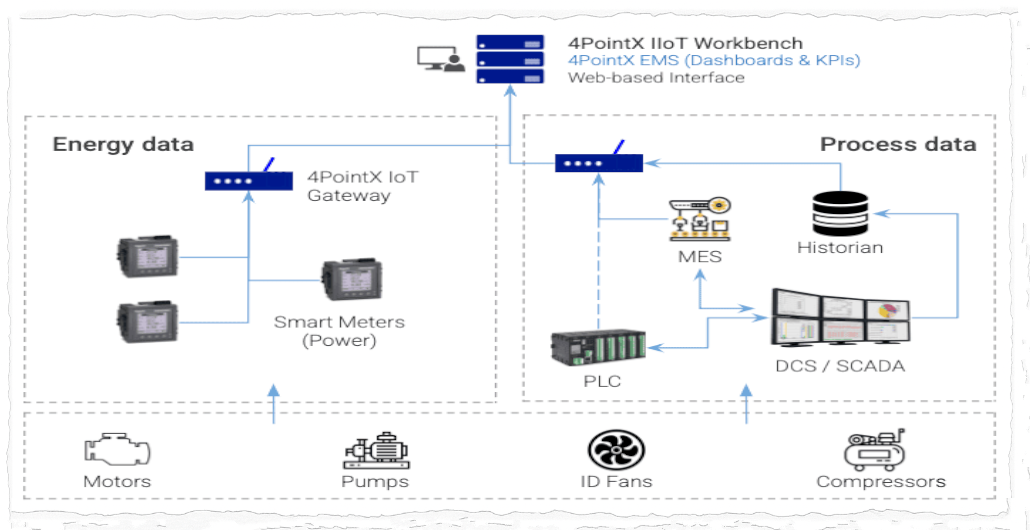

Easy to deploy and scale

Integrates with smart meters and MES for collecting Energy and Production data. Can scale to multiple plants and sites for a centralised deployment.

- On-prem server or Cloud deployment

- Ethernet, WiFi, SIM-based or LoRa