A comprehensive AI-enabled predictive maintenance plan starts with business understanding.

- Gartner Research, Published on December 04, 2018

Unforeseen asset downtime is a high operational risk to manufacturers, requiring deeper insights into asset health that IoT sensors and real-time condition monitoring alone are not able to deliver.

The condition indicators, although useful, do not give enough time to plan. For e.g., overall vibration is a lagging indicator as the defect already exists.

Also, setting the alert thresholds is a challenge. The varying nature of the process and product recipe leads to many false alarms.

4PointX PdM uses AI to automate the analysis. By correlating signals from both condition & process sensors, the solution detects anomalies (aka leading indicators) that usually show up as early as 60 days prior to the actual failure.

- Gartner Research, Published on December 04, 2018

Learn AI

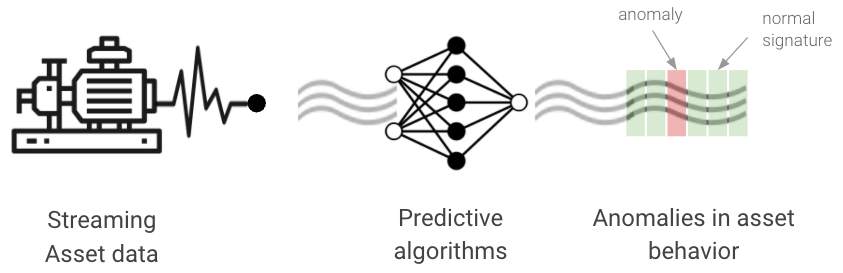

The Learn AI identifies the normal operating signatures of an asset by analysing the full spectrum of sensors - condition and process parameters.

Predict AI

The Predict AI scans every incoming asset data to compare and detect any unusual behavior that deviates from the normal operating signatures.

Explain AI

Use our Explain AI to know what tags are causing the anomaly and compare with similar signatures, if any, in the past.

Improve AI

As the user validates the anomalies, our Improve AI incrementally learns resulting in lesser and high-fidelity alarms.